- Home

-

About us

about/About us

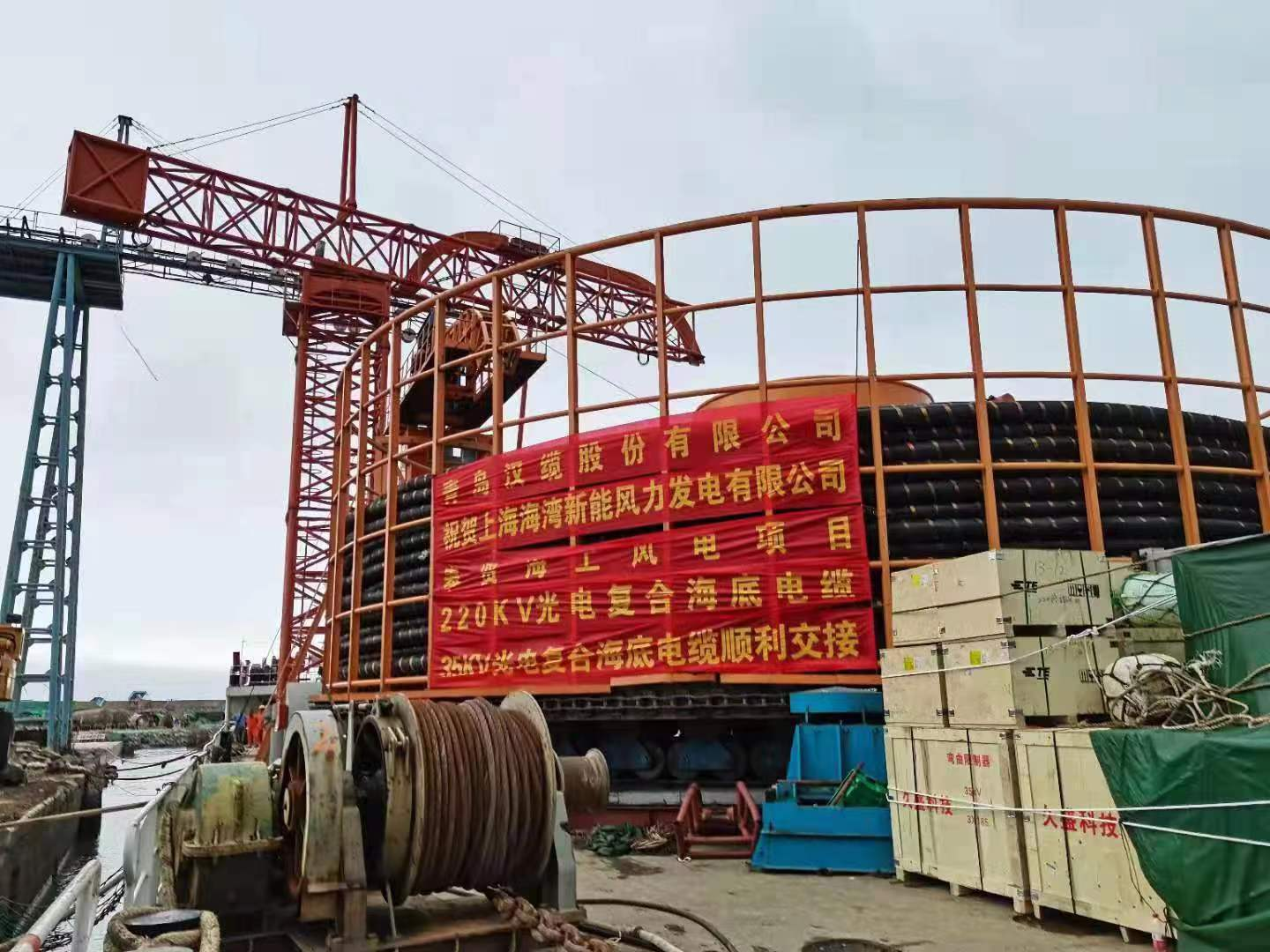

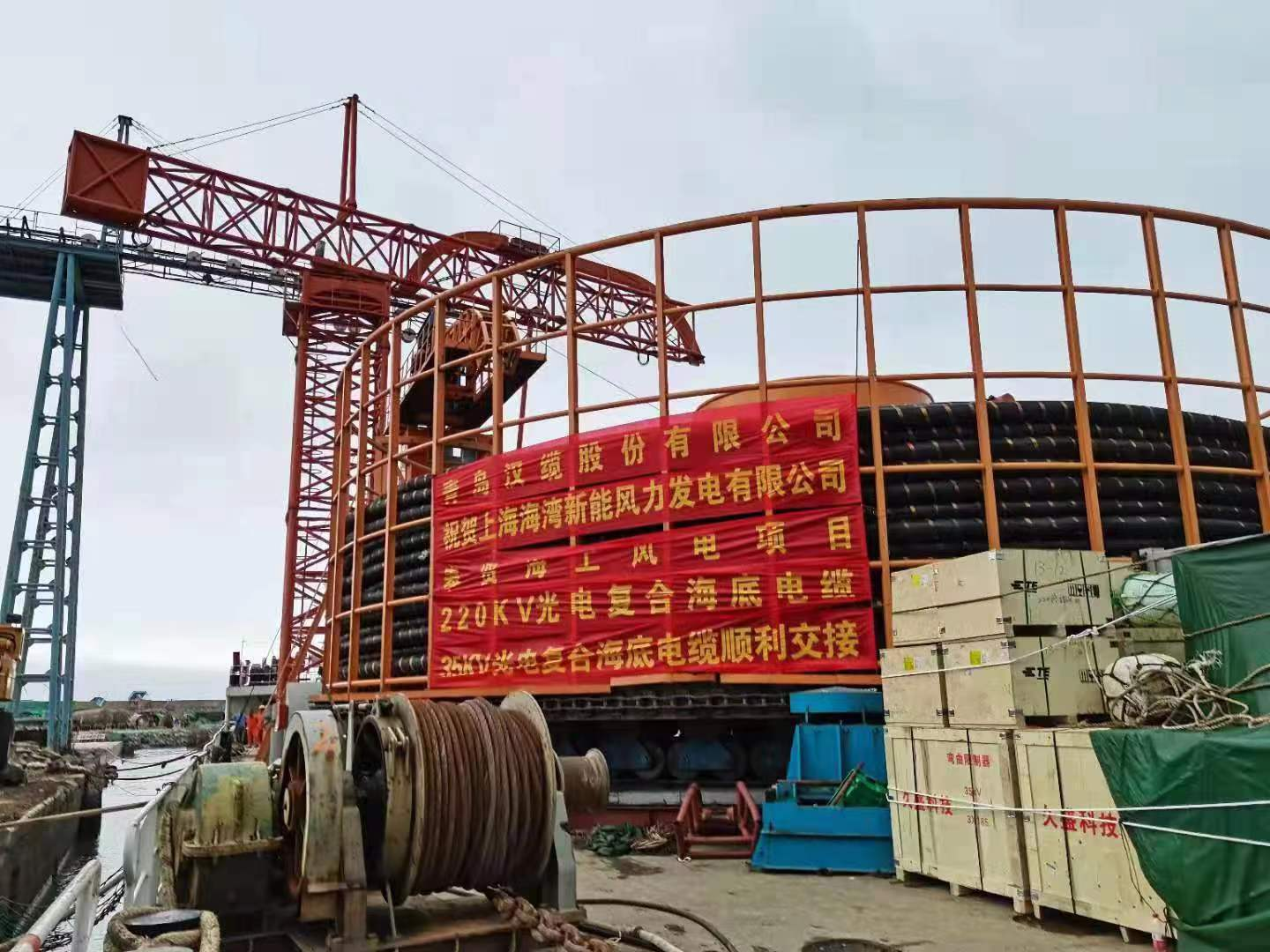

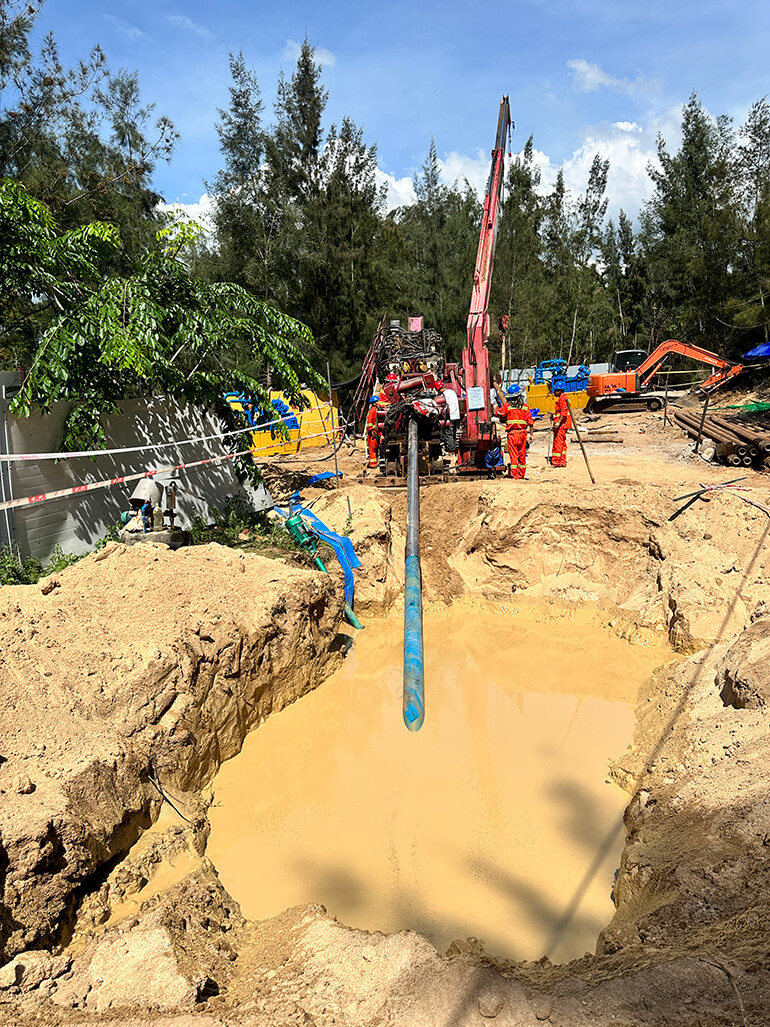

To transmit information and energy across the ocean.

-

What we do

Solution/What we do

Demand is the motive force to expand the market.

-

Products

Products/Products

Try harder and more attentively.

-

News

News/News

Do a project, erected a monument, cross friends with one side.

-

Client Zone

Client Zone/Client Zone

If we are right, customers are more correct.