Ductile cast iron is a metallic material consisting of elements such as iron, carbon and silicon, obtained through a casting process. It has excellent properties such as high strength, high toughness, and wear resistance, as well as good processability and corrosion resistance.

Pipe sections of joint type submarine cable protection pipe are connected by ball hinge head. This process can limit the bending of the whole pipe section within a certain range, effectively meeting the bending radius limit requirements for submarine cables. At the same time, the pipe section adopts a cross section structure for easy installation.

In nearshore, rocky and other underwater geological conditions, ductile iron joint sleeves can be installed to protect submarine cables.

According to the specifications of different submarine cables, submarine optical cables, and other cables, ductile iron joint sleeves also have various specifications for customers to choose, and can also be customized. The length of a single casing section is 500mm, 1000mm, 2000mm, etc., and the inner diameter of the pipe section starts from 40mm to 1000mm.

Products support customization, national logistics agency.

I. National and industrial standards followed by products

1. 《nodular cast iron》GB/T1348-2009;

2. 《Ductile iron pipes, fittings and accessories for water and gas》GBT13295-2013;

3. 《Casting dimensional tolerance and machining allowance》GB/T6414-1999;

4. 《Casting weight tolerance》GB/T11351 2017;

5. 《Comparison of surface roughness between block and casting surface》GB/T6060.1-1997;

II. Product specifications

1. The inner diameter of the tube is determined according to the outer diameter of the protected submarine cable;

2. Tube length: generally, the effective protection distance of each set is 500mm;

3. The joint types of spherical hinge are: ① sexual circular hinge; ② asexual circular hinge; ③ sexual spherical hinge; ④ asexual spherical hinge.

III. Configuration

The following criteria should be followed in the design of nodular cast iron joint tube:

1)The structural design requirements are conducive to increasing the adhesion of tube to the seabed

2)The body shall be free of burr, and the fit gap between the two segments shall be less than 2mm

3)The bending radius of integral pipe fittings shall not be less than 5m

4)It is required that the two sections of tube can move freely。

5)The tube body is required to be dipped with antirust paint or anti-corrosion treatment according to customer requirements.

IV. Mechanical property index

Material grade | tensile strengthσb/MPa(min) | Conditional yield strength RP0.2/MPa(min) | elongation A/%(min) | Brinell hardness HBM | Major group organizations |

QT450-10 | σb (MPa):≥450 | σ0.2 (MPa):≥310 | δ (%):≥10 | 160~210HB | Ferrite |

V. Impact resistance

Requirements for impact test:

Under the condition of low temperature (- 20 ± 2) ℃, the average value of impact energy of three patterns is not less than 12j, and individual value is not less than 9j.

VI. Metallographic requirements

The composition of as cast structure is graphite + ferrite (matrix structure) + pearlite

VII. Corrosion resistance

After special anti-corrosion treatment, nodular cast iron joint sleeve is not easy to be eroded by sea water, not easy to rot, and has a long protection period; under the service environment of sea water, it can guarantee a service period of 30 years.

VIII. Quality assurance and after sales service

Free warranty period: 3 years and above warranty period

Service response: problems found during installation, replacement within 24 hours (domestic)

Product Design Example:

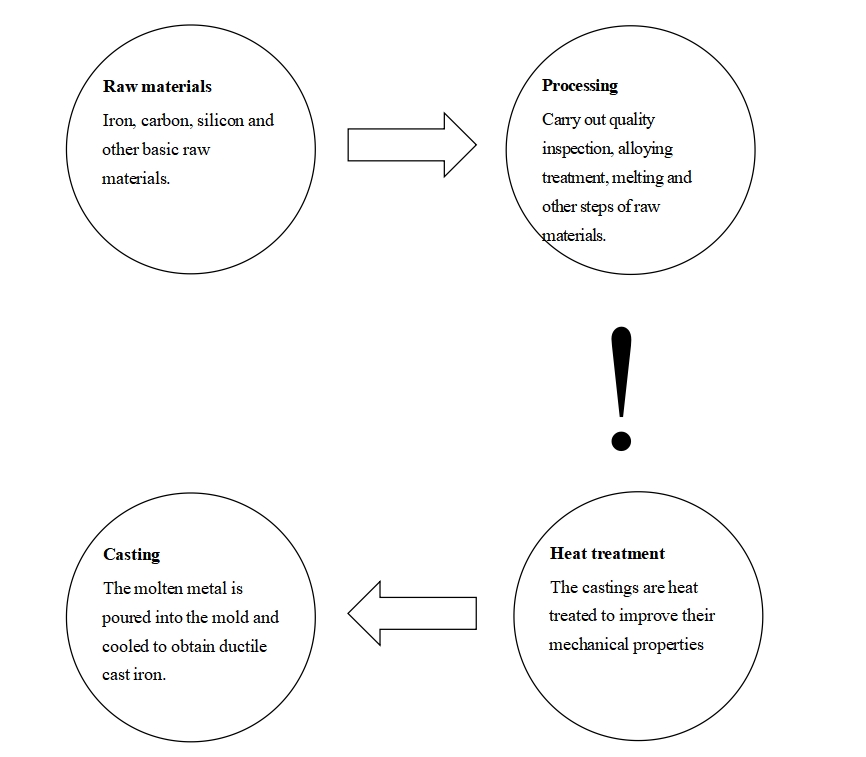

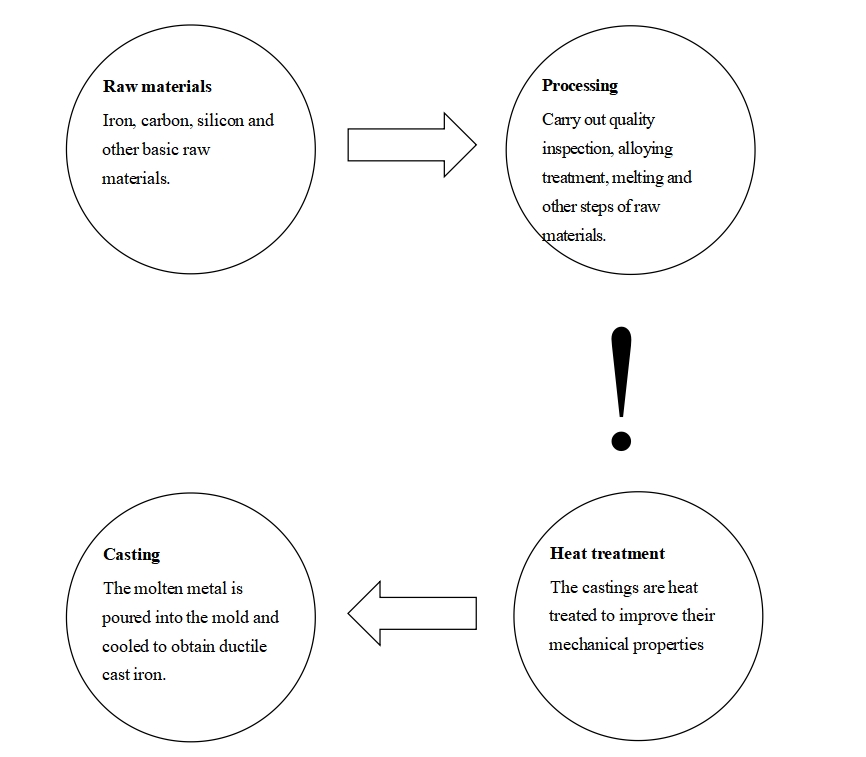

Production Process: